An elevator is a hoisting and lowering mechanism equipped with a car or platform that moves in guides in a substantially vertical direction and that transports passengers or goods, or both, between two or more floors of a building. A powered elevator employs energy other than gravitational or manual to move the car. The shaft in which the car travels is called a hoistway.

- A passenger elevator is an elevator used primarily to carry persons other than the operator

and persons necessary for loading and unloading. - A hospital elevator is a special type of elevator in which the cars are of suitable size and

shape for transportation of patients in stretchers or standard hospital beds and of attendants accompanying them. - A freight elevator is an elevator primarily used for carrying freight and on which only the operator and the persons necessary for loading and unloading the freight are permitted to ride.

- Dumbwaiters may be used in such multistory buildings as hospitals and restaurants to transport small items between levels. A dumbwaiter is a hoisting and lowering mechanism with a car of small load capacity and size. The car moves in guides in a substantially vertical direction and is used exclusively for carrying material. An undercounter dumbwaiter has its top terminal landing beneath a counter. The driving machine, usually winding drum but sometimes hydraulic for powered dumbwaiters, is placed at the bottom of the hoistway. For other types of dumbwaiters, the driving machine usually is electric traction for powered dumbwaiters and is located at the top of the hoistway. Dumbwaiters also may be hand operated.

Elevators are useful for moving large numbers of people and heavy loads between floors of a multistory building. Elevators often are required by local building codes for vertical transportation in buildings more than four stories high, but they are generally not accepted as a required means of egress in emergencies.

Although they are not relied on for this purpose, they nevertheless may be used as a means of escape by occupants in emergencies. Also, it is desirable that elevators be arranged for use by firemen in emergencies.

Two major types of elevators are in general use-electric and hydraulic.

- An electric elevator is a powered elevator to which energy is applied by an electric driving machine. This type is used exclusively in tall buildings and in most low buildings.

- An hydraulic elevator is a powered elevator to which energy is applied by a liquid under pressure in a cylinder equipped with a plunger, or piston. This type is used for low-rise freight service and may be used for low-rise passenger service where low initial cost is desired.

Passenger Elevators

Selection of and planning for passenger elevators should take into consideration the type of

building occupancy, anticipated traffic between floors, quality of service desired, life-cycle costs

of the elevator installation, and spaces needed for hoistways, lobbies and elevator equipment.

Also, the effects of these spaces on architectural floor plans and exterior elevations and on structural framing should be taken into account. Planning is complicated by the interdependency of these factors.

Space requirements for an elevator installation depend on the number of elevators to be

installed, car platform dimensions, car shape, arrangement of hoistways, and shapes and sizes

of lobbies. The number of elevators required depends on car capacity, volume of traffic

and the interval between arrivals of cars at any floor.

Interval is an important measure of the quality of elevator service. It is often taken as the

average time between elevators leaving the main lobby. The shorter the interval, the better is

the quality of elevator service, but the more expensive the elevator installation becomes because more, faster and larger elevators are needed to reduce an interval. Selection of an interval generally depends on the type of occupancy of a building. For example, an interval that may be considered satisfactory for an apartment building may be considered intolerable for an office building Interval is one of several factors determining travel time for passengers. Travel time is another measure of the quality of elevator service. The shorter the travel time between the arrival of a passenger at an elevator and arrival at the destination, the better is the quality of elevator service. Travel time preferably should be kept to less than one minute.

For a single elevator in a building, interval equals the round-trip time of the elevator. Round-trip time depends not only on the rated speed of an elevator but also on the probable number of stops a car has to make on its way up and down. In some cases, rated speed may have no influence on round-trip time because the short distance between stops does not allow sufficient time for the car to accelerate to full speed. Generally, however, round-trip time is composed of the time for a full-speed roundtrip run without stops plus time for accelerating and decelerating per stop, time for leveling at each stop, time for opening and closing hoistway and car doors, time for passengers to move in and out of the car, reaction time of operator, lost time due to false stops, and parking time at upper and lower terminals.

Number of Elevators.

- If a floor will be served by n elevators, the average interval will be the round-trip time T divided by Similarly, the number of elevators n needed to maintain a desired interval is obtained by dividing T by the interval.

- Selection of the number of elevators n is based also on the volume of traffic. Traffic flow for elevators is measured by the number of persons to be transported in 5-min. periods. The number of elevators required is calculated from the 5-min period with the maximum, or peak, traffic.

- For buildings under design, peak traffic generally can be estimated from studies of traffic flow in buildings of the same type located in the same or a similar neighborhood, or the peak flow may be predicted as a percentage of the probable building population, which in turn may be estimated from the total occupiable

floor area.

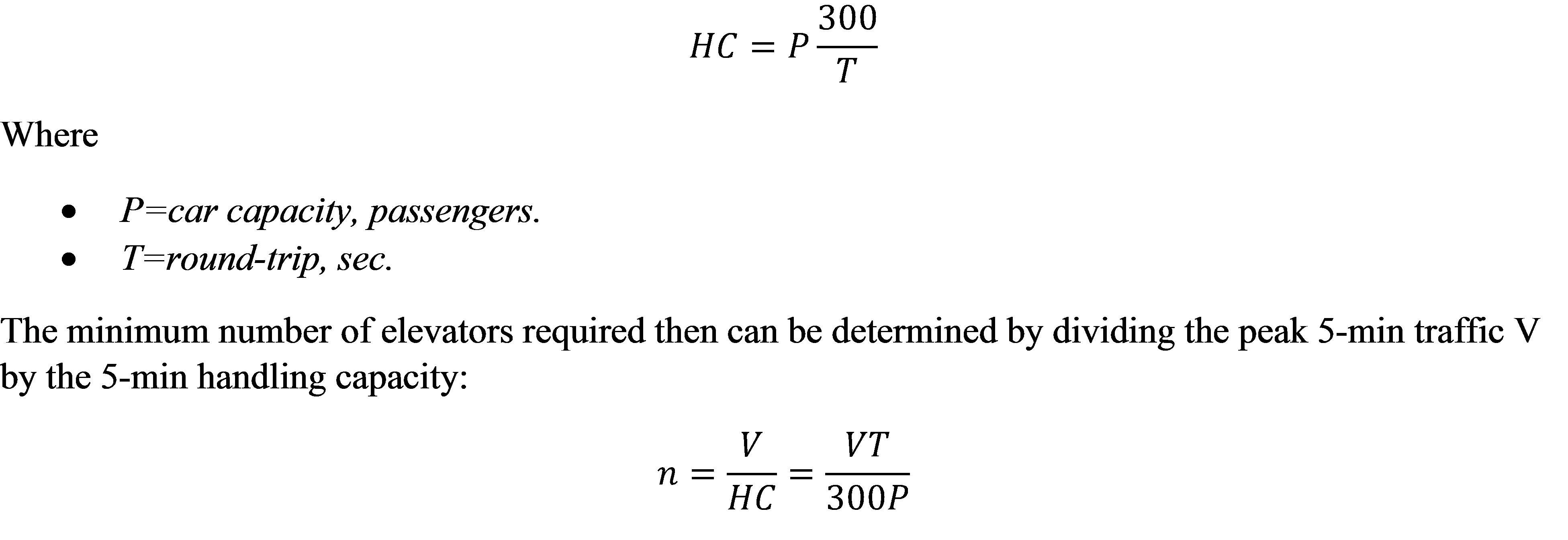

The maximum traffic-handling capacity of an elevator .car is the maximum number of passengers permitted in the car. This depends on the platform dimensions and rated capacity, Kg, of the car. The handling capacity (HC) in a 5-min or 300-sec, period then is:

- Thus, the number of elevators required is directly proportional to the round-trip time and inversely proportional to the car capacity.

- Thus, the number of elevators required is directly proportional to the round-trip time and inversely proportional to the car capacity.

Selection of the largest-capacity car available will reduce the number of elevators needed. Space needed for the elevator and initial cost, however, will be increased. Also, operating costs will increase, because the car often will travel unloaded or partly loaded. Hence, an optimum car is not likely to be the largest size available, Reduction of the round-trip time to reduce the number of elevators needed can be accomplished in several ways. For example, for tall buildings with long express-elevator runs, selection of faster cars will economically reduce round-trip time. The economics can be further improved byuse of multiple zoning. - Another way to decrease round-trip time is to reduce lost time at stops.

Simple Lift Number Design Guide:

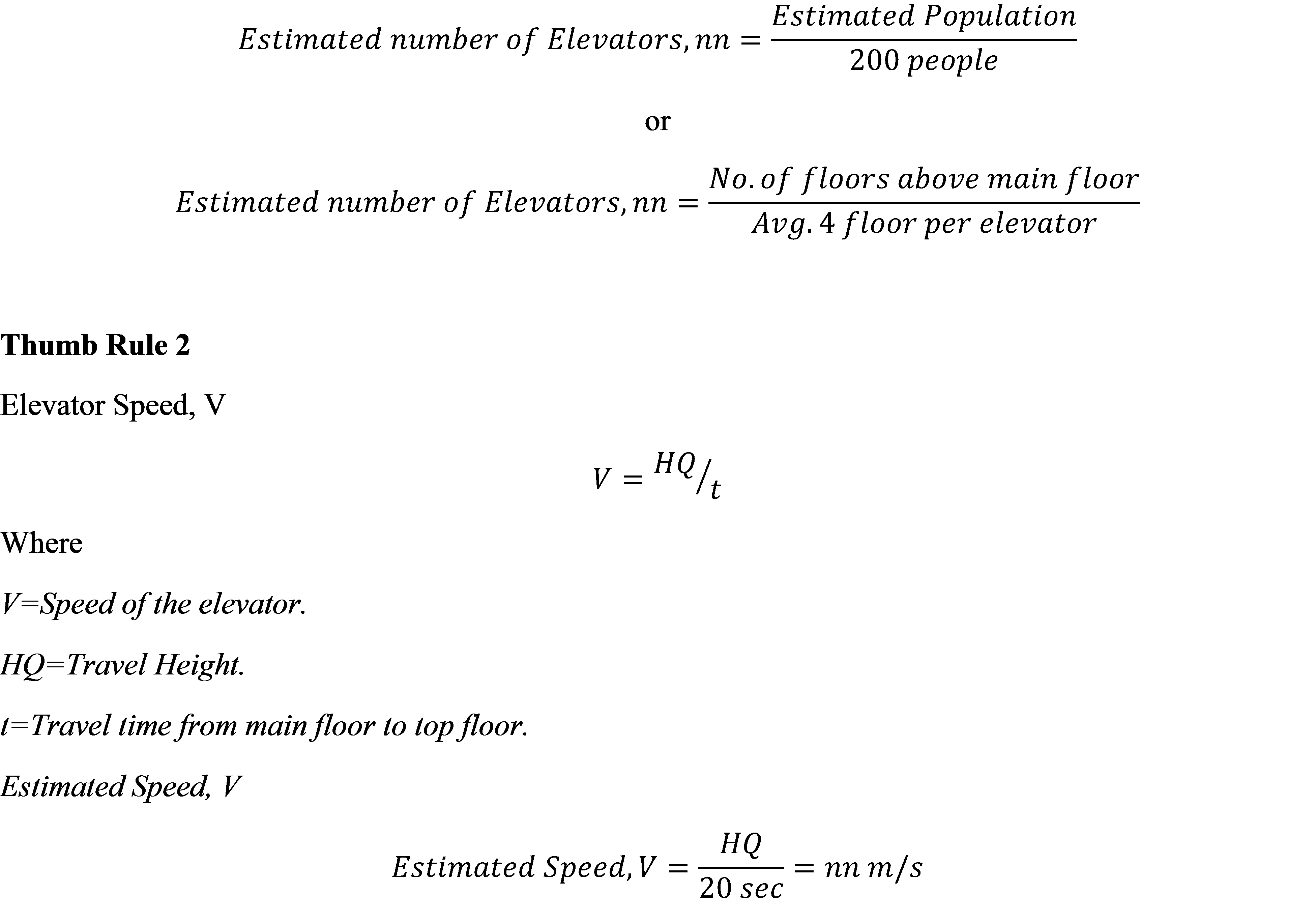

Thumb Rule 1:

- 200-250 persons per elevator

- 3-5 floors per elevator.

- 20-24 floors per elevator group.

Estimated number of Elevators,

Note:

This traffic calculation is only to be used as

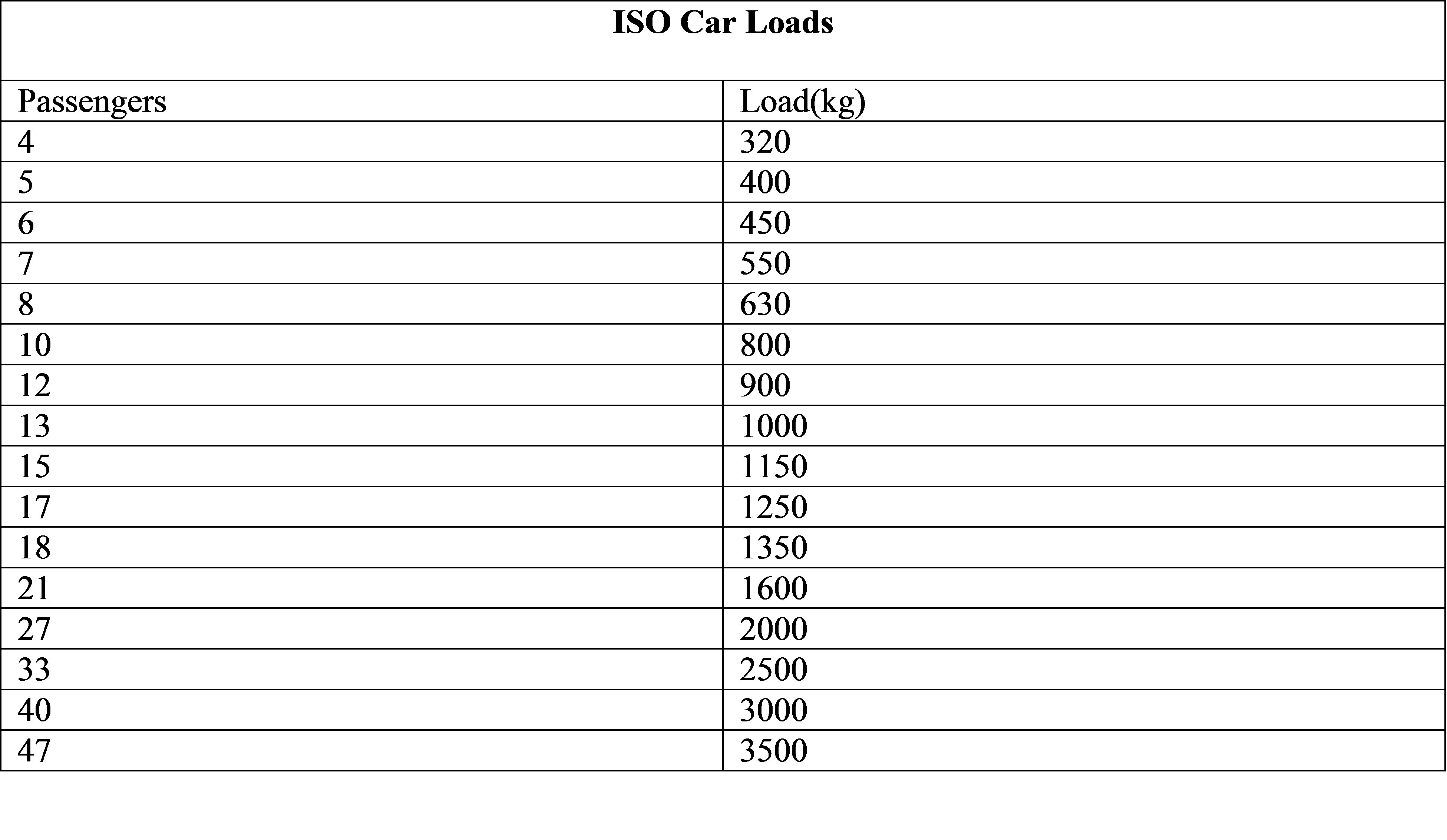

ISO Car Loads

ISO Lift Speeds

0.63m/s

1.00m/s

1.60m/s

1.75m/s

2.00m/s

2.50m/s

3.00m/s

3.50m/s

4.00m/s

4.50m/s

5.00m/s

6.00m/s