Generators can be used as power backup or as the primary source of electrical power. Generator size matters. If you undersize a generator, you won’t be able to power your equipment. If you oversize a generator, you will be wasting money. Under sizing the generator can be avoided by considering all of the loads that will be connected to the generator, and by determining the starting requirements (motor start) of electric motor-operated devices.

You must be sure that the generator you select is large enough to handle your present requirements and anticipated needs.

Basic steps on how to go about it.

1.Load Size Calculations.

To determine the right size generator, add up the total watts of all lights, appliances, tools, or other equipment to be connected to the generator. The total wattage will tell you the amount of electrical power required by your equipment and from there you can work out the minimum electrical input needed from a generator.

You can find wattage information either on the equipment’s silver nameplate or in the manufacturer’s guide. If wattage is not shown, but amps and volts are given, the following simplified formula

may be used:

Amps x Volts=Watts

Example, 10ampsx240 volts=2400 watts.

To determine kilowatts (kW), use the following formula:

1,000 Watts=1 Kilowatt

(Ex.2, 400 Watts/1,000= 2.4kW)

You can use a clamp meter to measure the load currents of the appliances/equipment that may not have the name plate rating. Voltage rating depends on whether the appliance or equipment requires single phase or three phase supply.

Once you get the total load, it is prudent to add 20%-25% future load expansion. This will cater for any future load additions.

To ensure that you don’t oversize the generator, make sure you incorporate the different load diversities in your calculations.

The total load wattage for your structure/equipment is in kilowatts (Kw). Kilowatts is the actual power that will be used by the load to produce a useful working output. However, generators are rated in kilo-volt-amperes (kVA). This is a measure of apparent power. That is, it tells you the total amount of power in use in a system. In a 100% efficient system kW = kVA. However electrical systems are never 100% efficient and therefore not all of the systems apparent power will be used to produce a useful work output.

You can convert between kVA and kW if you know the efficiency of the electrical system. Electrical efficiency is expressed as a power factor between 0 and 1: the closer the power factor is to 1, the more efficiently the kVA is being converted into useful kW.

International standards rate generators as having a power factor of 0.8. Power factor is very important for matching the size of your load to a generator.

kW to kVA

kW/Power Factor=kVA.

So, if the equipment you want to power has a total wattage of 240kW, the minimum size generator that could produce that would be a 300kVA

2.Define your running requirements

Will your generator be your primary power source?

A generator should not be operated at maximum capacity for more than 30 minutes. If you’re going to be using the generator as your main power supply, you’ll need to size for 70-80% capacity. As well as improving performance, leaving a 20-30% safety margin will also allow for future power requirements.

3.Analyze site conditions and access

Once you’ve calculated the load size and factored in your running requirements, you’ll have a good idea of the amount of electrical input needed from a generator. The next step is to confirm that your power requirements are feasible given the conditions and location of your site.

Site access and maneuverability have a big impact on how the generator is delivered and offloaded and this can also affect generator sizing. If access to the site is particularly narrow, uphill or off road then larger, less maneuverable vehicles may not be able to get on and off site. Similarly, if onsite space is limited there may not be enough room to extend the stabilizer legs necessary for offloading the generator, let alone enough space to operate the crane and position the generator.

Depending on the geographical location of your generator, you may also need to carry out generator derating. It is assumed the generator plate rating is as per sea level.

A technique called ‘Derating’ is employed to determine the generator’s performance under new ambient conditions. Derating is defined by Wikipedia as “the technique employed in power electrical and electronic devices wherein the devices are operated at less than their rated maximum power dissipation”.

Derating a generator depends on the manufacturer of the unit. Different manufacturers design generators using materials from different sources. Also, design developments are non-similar and so is the technique in many cases. All these can contribute to overall generator efficiency. Therefore, derating a generator is dependent on the manufacturing process. Different brands have different derating factors for estimating generator output under non-standard ambient conditions.

However, a general formula can be used to calculate close estimates for the output levels. The standard derating formula states that for every 305m above sea-level, a petrol, diesel, or liquid propane generator usually should be derated by 2–3% of its standard output. In case of generators using natural gas, the derating factor is typically closer to 5%.

4.Generator Installations.

Contact a licensed electrician or engineer to advice you before hiring or buying a generator. To ensure correct functioning, reliability and low maintenance costs generators must be installed correctly. To this end manufacturers provide detailed installation guidelines covering such topics as:

- Sizing and selection

- Electrical factors

- Cooling

- Ventilation

- Fuel storage

- Noise

- Exhaust

- Starting systems

5.Choose the generator and the generator supplier.

Other considerations include whether you need canopy type or open type generators, whether you need sound proof generators or not. Acoustic Canopies are, in effect, a large box lined with acoustic installation. Each acoustic canopy also has purpose built louvers for free flow ventilation and to reduce the external sound levels. The most common level of sound proofing for generators is the E.U. standard of 80dbA @ 1 metre open field conditions. When the generator is to be permanently sited outside, that’s when you need the generator to be its own acoustic weather proof and lockable canopy, weatherproof and secure.

Before you buy the generator, take note of the seller’s years of experience, whether they are a full service dealer or small commissioned broker. Sometimes the suppliers/installers charge hefty maintenance charges. Therefore you need to be careful with this since it may prove to be costly in the long term.

6.External Fuel Tank.

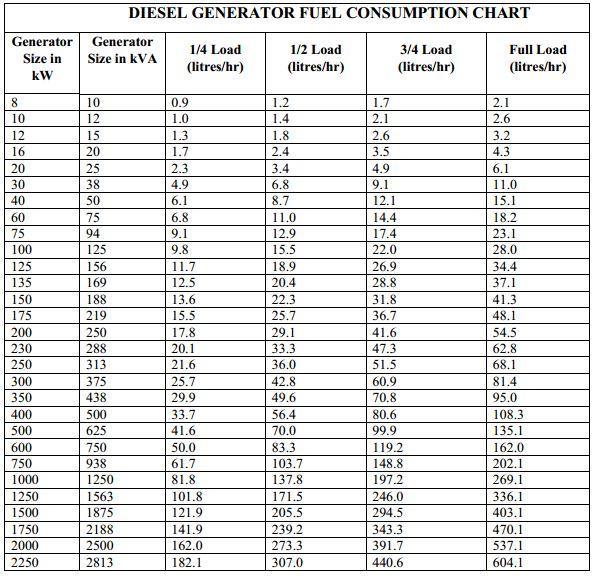

The external fuel tank size depends mainly on the amount of time you would want the generator to run continuously before refilling the tanks. This can be easily calculated by taking note of the rate of consumption of the fuel by the generator in Liters/hour at the given loading, say at 25%, 50%, 75% or 100% load. This data is normally given in the generator manuals/catalogues. Check sample data at the bottom of this post. You can download the chart here, ” DIESEL GENERATOR FUEL CONSUMPTION CHART”

7.UPS – Generator Compatibility

A.Passive (standby or off-line) and Line Interactive UPS

These technologies are most common for personal workstations and point of sale applications They are typically single phase equipment with size ranges of 350 VA – 2000 VA for passive and 500 VA to 5000

VA for line-interactive.

Passive UPS’s are the simplest type Under normal conditions AC power passes straight through to the UPS load When the input power supply goes outside of specifications, the UPS transfers

the load from input power to the internal DC to AC power inverter Passive UPS’s do not correct for voltage or frequency deviations under “normal” operation.

Line-interactive is similar to the passive technology except it has circuitry that attempts to correct for standard voltage deviations Frequency deviations under “normal” power operation are not corrected.

Equipment Notes:

These devices tend to be electrically / harmonically very noisy. A single small UPS is not a significant concern, but applications with multiple UPS’s can be problematic Passive UPS technology typically has normal tolerances of 10-25% on voltage and 3 hertz on frequency. If the input source goes outside of

these tolerances, the UPS will switch onto the UPS battery source .Some line-interactive units may have frequency tolerances factory set to 0 5 hertz .These units will need to have their frequency tolerance

increased to a minimum of 2 hertz

Generator Sizing Recommendation:

Limit the total UPS loading to 15% – 20% of the generator capacity.

B.Double-Conversion

This technology is most common for critical load applications. Double-conversion UPS’s constantly rectify AC to DC and then invert the DC back into AC. This configuration results in an output that corrects for voltage and frequency deviations. There are single and three phase models covering small through large applications. Most UPS applications larger than 5000 VA use double conversion technology .This approach is also the preferred technology for generator applications.

Equipment Notes:

Double-conversion UPS’s that are single phase or unfiltered three phase models tend to create a significant level of electrical/ harmonic noise. This is illustrated by harmonic current distortions that are greater than 35% . When three phase models are supplied with harmonic filters (current distortion less than 10%), this concern is no longer an issue.

Generator Sizing Recommendation:

- Single phase models: Limit the total UPS loading to 25% of the generator capacity.

- Single phase Minuteman UPS models: Limit the total UPS loading to 50% of the generator capacity.

- Three phase models without filters (current distortion > 30%): Limit the UPS loading to 35% of the generator capacity.

- Three phase models with filters (current distortion < 10%): Limit the UPS loading to 80% of the generator capacity.

8.Other considerations.

Exhaust pipe size design. How will the fumes and heat be exhausted? Ventilation of the indoor generator rooms is very important and it ought to be done by a qualified engineer.

Advantages of choosing the right size generator.

- No unexpected system failures

- No shutdowns due to capacity overload

- Increased longevity of the generator

- Guaranteed performance

- Smoother hassle-free maintenance

- Increased system life span

- Assured personal safety

- Much smaller chance of asset damage

Kindly extent your diesel consumption data up to 1000KVA for me to get it right because i have a 700KVA diesel generator and all along i have been estimating the diesel consumption per hour.

Hello Emily. The post has has been updated to capture your request. Thank you.

I didn’t know that your wattage total can help you determine the size generator that you will need. My brother would like to open an office construction company and needs to make sure that the lights in his building are functional to prevent injuries while handling power tools. I’ll let him know that he should consider how much power he will need so that he can choose a generator properly.

Hello Benard the total power of my plant is 1700kw.Can you suggest to me which

size and type of genset can I use and if it possible to use two sets in parallel so that when the load is less one set will run and when the load increases,the other set will automatically switch on.Thanks.

Rgds,

Felix

Allowing a 0.8 Power Factor makes your total apparent power=1700/0.8=2125kVA.

Generators are run at 70-80% their rated capacity, so allowing for 75%, we know have =2833kVA.

Allowing for future load expansion, say 20%, brings us to new kVA, 3400kVA.

So now you may just need to synchronize two generators whose cumulative power rating is 3400kVA(2720kW). If you can get two 1700kVA(1360kW) gensets, this would be the ideal. But budget constraints and other requirements may make you go for lower ratings. Check out this model by Caterpillar brand, http://s7d2.scene7.com/is/content/Caterpillar/C10219129

I just came across this site on some resource I downloaded from LinkedIn. There is so much to learn from your site. Keep up this great work!